Aluminum foil tape is a versatile and indispensable tool in the world of repairs, maintenance, and DIY projects. With its heat resistance, durability, and adhesive strength, it's a go-to solution for sealing, patching, and insulating a wide range of surfaces and materials. Whether you're a seasoned pro or a DIY enthusiast, mastering the art of aluminum foil tape can elevate your projects to new heights. In this comprehensive guide, we'll explore the various applications and techniques for using aluminum foil tape effectively.

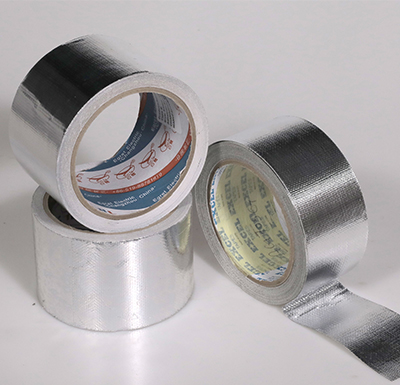

Before diving into its applications, let's first understand what aluminum foil tape is. It's typically composed of a thin layer of aluminum foil coated with a strong adhesive on one side. This construction provides excellent heat resistance, moisture resistance, and durability, making it suitable for a wide range of tasks.

Aluminum foil tape finds applications across various industries and settings. Here are some of its common uses:

1. HVAC Systems

Aluminum foil tape is widely used in heating, ventilation, and air conditioning (HVAC) systems for sealing ducts, joints, and seams. By creating airtight seals, it helps prevent air leaks, improving energy efficiency and indoor air quality. When applying aluminum foil tape to HVAC systems, ensure that the surfaces are clean and dry for optimal adhesion.

2. Insulation

Another common application of aluminum tape for sale is in insulation projects. It's used to secure and seal insulation materials such as fiberglass or foam board. By enhancing thermal efficiency and maintaining the integrity of the insulation barrier, aluminum foil tape helps reduce heat transfer and energy consumption.

3. Pipe Wrapping

Aluminum foil tape is also employed for wrapping and sealing pipes, providing protection against moisture, corrosion, and temperature fluctuations. Whether used in plumbing systems or industrial piping, aluminum foil tape helps prevent leaks and extends the lifespan of the pipes.

4. Ductwork Repairs

In industrial and commercial settings, aluminum foil tape, such as HVAC aluminum foil tape, is commonly used for repairing damaged ductwork, sealing punctures, or reinforcing joints. Its durable and long-lasting adhesive properties make it an ideal solution for addressing leaks and ensuring the efficient operation of duct systems.

5. Electrical Applications

Aluminum foil tape plays a crucial role in electrical applications for shielding and grounding purposes. It helps protect electronic components from electromagnetic interference (EMI) and radiofrequency interference (RFI), ensuring the reliable performance of electrical systems.

Now that we've explored the various applications of aluminum foil tape, let's delve into some tips for using it effectively:

1. Surface Preparation

Before applying aluminum foil tape, it's essential to prepare the surface properly. Clean the surface to remove any dirt, dust, or grease that may hinder adhesion. Additionally, ensure that the surface is dry to prevent moisture from affecting the tape's performance.

2. Proper Application

When applying aluminum foil tape, it's crucial to do so smoothly and evenly. Start by peeling off a small section of the backing and carefully align the tape with the intended surface. Slowly press the tape onto the surface, ensuring good contact to create a secure seal.

3. Overlap Seams

When sealing seams or joints with aluminum foil tape, it's advisable to overlap the tape slightly. This helps ensure a tight and leak-proof seal, preventing air or moisture from penetrating the seam. Be sure to apply pressure along the overlapped area to ensure a strong bond.

4. Press Firmly

After applying aluminum foil tape, it's essential to press it firmly onto the surface to enhance adhesion. You can use a roller or your fingers to press the tape firmly and remove any air bubbles. This step helps ensure that the tape adheres securely to the surface, providing a long-lasting seal.

5. Trim Excess

Once the tape is applied, trim any excess with scissors or a utility knife for a neat and professional finish. This not only enhances the aesthetics of the project but also helps prevent the tape from peeling or becoming damaged over time.

1. Peel Slowly

Start by peeling the tape slowly from one corner. Pulling too fast can leave adhesive residue behind. For tough areas, use a plastic scraper to gently lift the tape without damaging the underlying surface.

2. Heat the Tape

If the tape is stubborn, apply heat using a hairdryer or heat gun. The warmth will soften the adhesive, making it easier to peel off without leaving residue. Be careful not to overheat the surface.

3. Use Adhesive Remover

For any remaining adhesive, apply an adhesive remover or rubbing alcohol to the area. Let it sit for a few minutes before wiping it off with a clean cloth. This will help dissolve the sticky residue.

4. Clean the Surface

Once the tape and residue are removed, clean the surface with soapy water or a mild cleaner to remove any leftover adhesive remover and restore the surface.

In conclusion, aluminum foil tape is a versatile and invaluable tool for a wide range of applications. Whether you're sealing ducts, insulating pipes, or repairing HVAC systems, mastering the art of aluminum foil tape can significantly enhance the quality and durability of your projects. By understanding its applications and following proper techniques for surface preparation and application, you can achieve professional-quality results with ease. So, the next time you embark on a repair or DIY project, reach for aluminum foil tape and unleash its power to elevate your creations to new heights.