Cloth tape is a versatile adhesive product constructed with a woven fabric backing—typically cotton, polyester, or a blend of both—combined with a pressure-sensitive adhesive. The fabric provides excellent tensile strength and flexibility, allowing the tape to conform easily to irregular surfaces. Its woven structure also enhances durability and tear resistance, making it suitable for demanding conditions. Cloth tape comes in a variety of grades, thicknesses, colors, and adhesive formulations, including rubber-based and acrylic adhesives. It is designed to offer a reliable bond, good aging characteristics, and stability under varying temperatures and humidity levels. The combination of fabric strength and adhesive performance makes cloth tape a reliable solution for situations where both resilience and ease of use are essential.

Cloth tape is primarily composed of a woven fabric backing and an adhesive layer. The backing is typically made from materials such as cotton, polyester, or a cotton-polyester blend. This woven construction gives the tape its strength, flexibility, and resistance to tearing. The fabric allows the tape to conform to uneven surfaces and maintain its integrity under mechanical stress.

The adhesive applied to the fabric backing is usually rubber-based, acrylic-based, or made from hot melt compounds. Each type offers different properties—rubber adhesives provide strong initial tack, acrylic adhesives offer better aging and weather resistance, while hot melt adhesives balance both. In some cases, the tape may also include a protective coating to enhance resistance to moisture, abrasion, or UV exposure.

Duct tape is a strong, pressure-sensitive adhesive tape with a fabric-reinforced backing, typically coated with polyethylene. It is known for its durability, flexibility, and water-resistant properties. Originally developed for military use, duct tape features a rubber-based adhesive that bonds well to a wide variety of surfaces. The tape is easy to tear by hand and often comes in a range of colors, with silver or gray being the most common.

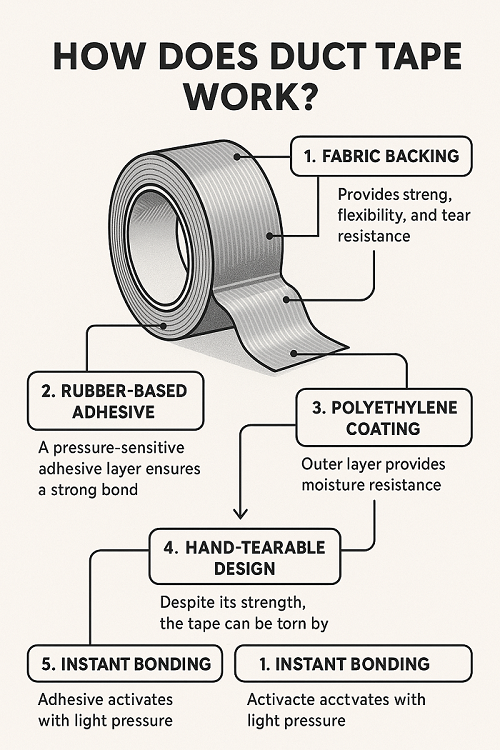

1.Fabric Backing

The woven fabric layer provides strength, flexibility, and tear resistance, allowing the tape to hold under tension and conform to irregular surfaces.

2.Rubber-Based Adhesive

A pressure-sensitive adhesive layer ensures a strong bond to many surfaces such as metal, plastic, fabric, and wood.

3.Polyethylene Coating

This outer layer gives the tape a smooth finish and makes it resistant to moisture and environmental exposure.

4.Hand-Tearable Design

Despite its strength, the tape can be torn by hand for quick and easy application without tools.

5.Instant Bonding

The adhesive activates with light pressure, enabling fast and reliable sticking without the need for heat or water.

Cloth tape and duct tape each offer unique advantages, but when it comes to strength and durability, duct tape generally outperforms cloth tape. This is due to several key factors:

1.Adhesive Strength

Duct tape uses a stronger rubber-based adhesive that provides a stronger, more lasting bond, especially on rough or uneven surfaces. Cloth tape’s adhesive is often less aggressive.

2.Backing Material

While cloth tape uses a fabric backing that offers good flexibility and strength, duct tape's fabric backing is reinforced with a polyethylene coating, giving it more resistance to wear, moisture, and stress.

3.Tensile Strength

Duct tape usually has higher tensile strength, meaning it can handle more force before breaking or tearing compared to cloth tape.

1. Adhesive Strength

Cloth tape typically utilizes a milder adhesive, which is sufficient for light-duty applications such as bundling, labeling, and temporary fixes. Its adhesive is designed to provide a secure, but not overly strong, bond, making it more suitable for surfaces that don’t require heavy adhesion.

In contrast, duct tape features a stronger rubber-based adhesive, designed to form a durable bond with a variety of surfaces, including rough, uneven, or textured materials. The adhesive in duct tape ensures reliable adhesion even under challenging conditions, making it the ideal choice for demanding applications requiring long-lasting performance.

2. Backing Material

Cloth tape is constructed with a woven fabric backing, often made from cotton, polyester, or a blend of both, which offers a combination of flexibility and resistance to tearing. While this backing provides sufficient strength for lighter tasks, it lacks the reinforced qualities of duct tape. Duct tape, on the other hand, has a reinforced fabric backing that is often treated with a polyethylene coating, which enhances the tape's overall durability and resistance to external factors such as abrasion, moisture, and UV exposure. The added reinforcement in duct tape ensures it can endure tougher conditions without compromising its structural integrity.

3. Strength and Durability

Cloth tape is generally designed for applications requiring moderate strength, such as holding light materials in place or providing temporary fixes. However, its strength and durability are limited compared to duct tape.

Duct tape is renowned for its high tensile strength, which allows it to withstand significant force without tearing or breaking. This makes duct tape particularly well-suited for heavy-duty applications such as construction, automotive repairs, and industrial environments, where a higher level of durability and long-term adhesion is critical.

4. Water and Weather Resistance

Cloth tape is not specifically designed to withstand moisture or extreme weather conditions. Its adhesive can weaken when exposed to water or humid environments, reducing its overall performance in outdoor or wet applications.

In contrast, duct tape’s polyethylene coating and robust adhesive make it inherently water-resistant. This feature allows duct tape to perform reliably in various environmental conditions, including exposure to rain, humidity, and fluctuating temperatures. As a result, duct tape is the preferred choice for outdoor repairs and applications that demand moisture resistance.

5. Flexibility and Tearability

Cloth tape is more flexible compared to duct tape, which makes it easier to handle and conform to irregular surfaces. Its flexible nature makes it an ideal choice for lighter tasks that require a high degree of maneuverability, such as wrapping and bundling.

Additionally, cloth tape can be easily torn by hand without requiring scissors or tools. Duct tape, although still flexible, has a more rigid structure due to its reinforced backing and stronger adhesive. While duct tape can also be torn by hand, it is less flexible and may require more force for tearing, especially when applied to tougher surfaces.

| Feature | Cloth Tape | Duct Tape |

| Stickiness | Less sticky, good for light jobs. | Very sticky, strong hold for tough jobs. |

| Backing | Soft fabric, tears easier. | Strong fabric with plastic, harder to tear neatly. |

| Strength | Okay for holding light things. | Very strong, good for heavy-duty fixes. |

| Waterproof | Not very waterproof. | More waterproof. |

| Bendability | Bends easily around shapes. | Can bend, but stiffer. |

| Tearing by Hand | Easy to tear. | Can tear, but needs more effort. |

Within the domain of general maintenance and repair, cloth tape proves invaluable for provisional mending of various articles, capitalizing on its robust adhesion and resistance to tearing. Furthermore, it exhibits utility in the reinforcement of compromised or weakened structural elements. Certain variants of cloth tape possess water-resistant properties, rendering them suitable for the interim sealing of breaches or apertures. Its inherent strength also facilitates the secure bundling and retention of items such as wiring, cabling, and conduits.

In industrial and automotive contexts, cloth tape finds application in masking procedures, effectively safeguarding surfaces during abrasive processes like sanding and painting within automotive and manufacturing environments. It is also employed for the harnessing and organization of wiring and cabling within vehicles and machinery. Specialized forms of cloth tape are engineered for the secure sealing of HVAC ductwork, while others provide temporary solutions and component fixation in automotive repair scenarios.

The arts, entertainment, and photographic industries rely extensively on a specific type of cloth tape known as gaffer tape. This product is favored for securing cables, delineating stage layouts, and executing temporary repairs due to its capacity for clean removal without leaving adhesive residue. Additionally, cloth tape plays a role in stage and set design for affixing props, indicating positions, and facilitating temporary constructions.

In the medical and healthcare fields, the strength and conformability of cloth tape render it appropriate for securing wound dressings and splints, ensuring the stable positioning of medical bandages and supportive devices.

| Application Area | Cloth Tape | Duct Tape |

| General Repair | Temporary fixes, reinforcement, temporary sealing, bundling wires/cables | Temporary sealing of pipes/ducts, quick household repairs |

| Industrial/Automotive | Masking, wire harnessing, sealing specific ducts, temporary auto fixes | Surface protection, temporary auto repairs, industrial bundling |

| Arts/Entertainment/Photo | Securing cables (gaffer tape), stage marking, temporary prop fixes | Crafting and DIY projects |

| Medical | Securing dressings and splints | Emergency makeshift bandages/splints |

| Other | Home DIY, some insulation, safety marking, bookbinding | Bundling items, handling unexpected situations |

Duct tape is widely recognized for its versatility and is employed in a variety of applications across both household and industrial settings. One of its most common uses is in sealing. Duct tape is highly effective in creating temporary seals for pipes, ducts, and HVAC systems, especially when dealing with leaks or cracks. Its water-resistant properties make it suitable for use in both dry and damp environments, where it can prevent further damage until a more permanent solution is found. Additionally, it is frequently used in surface protection, such as masking off areas during painting or sanding to shield them from damage.

Another key application of duct tape is in repairs. It can quickly and effectively fix a wide range of broken items, from household appliances to automotive components. Whether it’s patching holes, sealing cracks, or reattaching parts, duct tape provides a strong and durable bond to various materials, including metal, plastic, wood, and fabric. Its ability to withstand stress and pressure makes it ideal for temporary fixes in both home and industrial environments. Bundling is also a common use for duct tape, as it can securely hold cables, wires, and other materials together, ensuring they are organized and protected.

Duct tape's adaptability extends beyond traditional repairs. It is often used in crafting and DIY projects, where it serves as a creative and functional tool. Whether it’s used to make custom items, patch up clothing, or create art, duct tape’s range of colors and patterns adds a unique touch to any project. In emergency medical situations, duct tape has even been used for makeshift bandages or splints, showcasing its utility in unexpected circumstances. From everyday tasks to extreme environments, such as space exploration, duct tape continues to prove itself as an indispensable tool with applications far beyond what might be initially imagined.

1.Is duct tape waterproof or water resistant?

Duct tape is water-resistant, meaning it can withstand exposure to moisture and damp conditions. However, it is not fully waterproof and may lose adhesion over time when exposed to constant or submersion in water. For prolonged exposure to water, more specialized tapes or sealants are recommended.

2.Is duct tape good for fixing anything?

Duct tape is highly versatile and effective for a wide range of temporary repairs, including fixing cracks, sealing gaps, and holding materials together. While it provides a strong, durable bond, it is not suitable for permanent repairs, particularly on heavy-duty or high-stress applications where a more robust solution is required.

3.Is duct tape heat resistant?

Duct tape has a moderate level of heat resistance, typically withstanding temperatures ranging from 200°F to 250°F (93°C to 121°C), depending on the brand. However, it is not designed for high-temperature applications, and prolonged exposure to extreme heat can cause the adhesive to weaken, leading to failure. For higher heat tolerance, specialized tapes are recommended.

is cloth tape breathable

Yes, cloth tape is breathable due to its woven fabric structure, which allows air to pass through. This makes it suitable for applications on materials that require ventilation, such as in medical or sporting contexts.

is cloth tape waterproof

Cloth tape is generally not waterproof. While it offers some resistance to moisture, it is not designed for prolonged exposure to water and may lose its adhesive properties under wet conditions.

is cloth tape micropore

Cloth tape is not typically micropore. While some cloth tapes may have a porous surface, they are not specifically designed for micropore functionality, which is typically seen in medical or filtration tapes that allow air and moisture to pass through.

Can cloth tape be used on skin?

Cloth tape can be used on the skin, but it is not recommended for long-term wear. While it is gentle enough for temporary use, it may cause irritation or discomfort if left on for extended periods. Medical-grade adhesive tapes are a better option for prolonged skin contact.